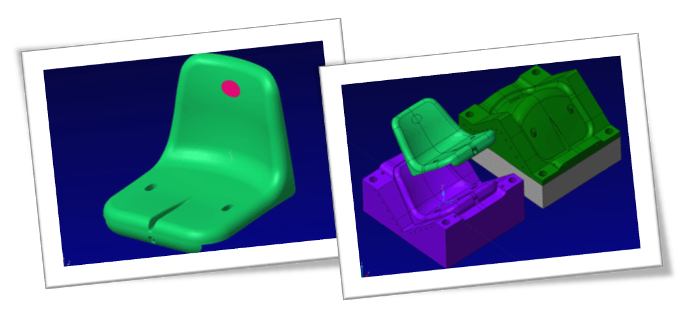

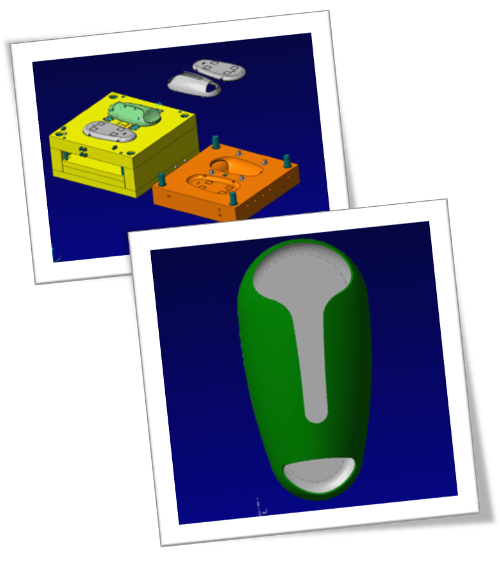

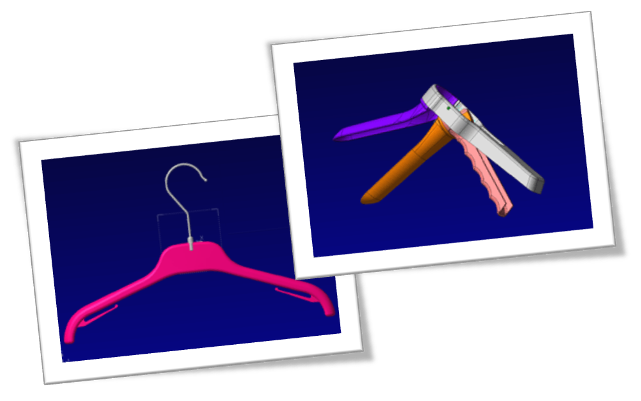

The design of the mold is made entirely of CAD / CAM programs on computers last generation. Fixing the product design program is up to the last detail, so that the end product we get is identical to the original! Our company undertakes to implement every idea from the initial conception phase of the original design, until the formation of the finished product, so perfectly adapted to the specific needs and requirements, as opposed to competing proposals based on ready and generalized standards.

If the mold design, enjoys working in the CNC, while manufactured and other data from other machines. This completes the final mold (injection) and goes through inspection and testing. Subsequently, at the request of the customer, can produce thousands of plastic parts, durable, and excellent quality, the final mold. This saves the customer from a lot of unnecessary costs

With the experience gained in design and construction, we reduce the delivery time at a minimum.

The tremendous flexibility offered by the exact design of the computer allows us to manufacture a wide range of useful everyday products, and specialized tools, educational, scientific, medical, and other applications.